This post is also available in: Español (Spanish)

Software

Gestión integral

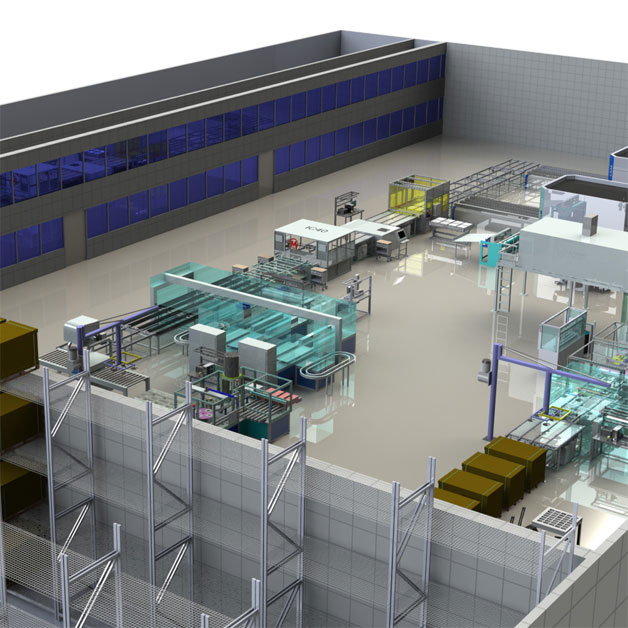

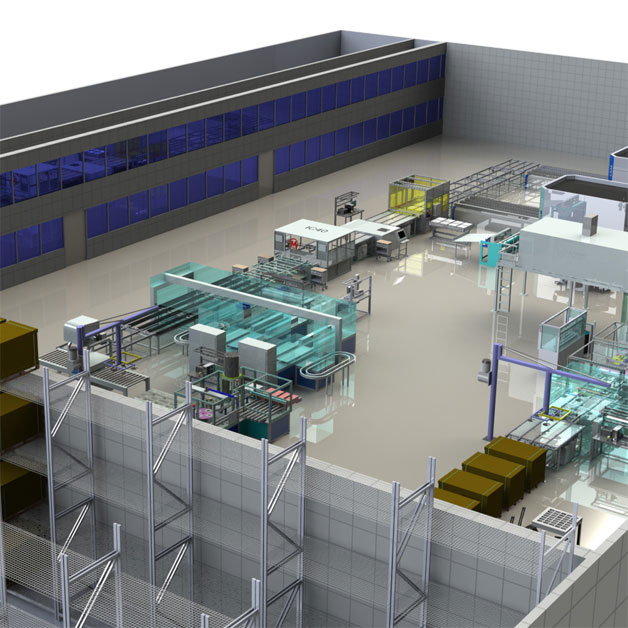

After a long experience in manufacturing projects and production process management, Aurinka has developed a software that allows the overall management of a company and its factory.

The software is fully configurable and modular; it can be addapted to the peculiarity of any customer production process.

ERP

LOGISTICS, PROCUREMENT AND SALES

- Suppliers management

- Purchase orders

- Raw material cualification and approval

- Control of supplier orders

- Supply management and delivery

- Internal consumption

- Losses, breakages and returns

- Inventory management

- Customers

- Offers

- Projects management

- Orders

- Planning (MRP)

ACCOUNTING

- General accounting of the company

- Countable book entries

- Assets

- Official reports

- Customized reports

- Treasury management

- Collections and payments

AFTER-SALES

- Installations and Guarantees

- Analysis of Energy yield and performance of installations

- In situ interventions

- Management of technical audits and reports

HUMAN RESOURCES

- Contracts

- Schedules and time tables

- LRP

- Training

- Absence management

MES

TRACEABILITY AND PRODUCTION

- Digital Working Progress Slip of the product with step-by-line record of times and operators

- Input of materials and their lot numbers

- Consumption

- Costs control

- Machines repair management

- Electrical controls

- Quality controls

- Warehouse control

MANUFACTURING ORDERS

- Process recipes control

- Bill Of Materials for the product order

- Electrical restrictions specifications

- Physical specifications

- Quantity control

KEY PERFORMANCE INDICATORS ( KPIs)

- Real-time monitor

- Throughput in different control points

- Breakage and defects rates

- Downtimes

- Process incidents

- Early warning and actions based on process results

- Control of manufacturing time

- Control of process conditions

LABORATORY MANAGEMENT

- Registration and test controls (degradation tests, I-V curve test, etc)

- Peel tests, gel content determination, lamination temperature control, etc.

- Raw materials selection, tests, approval and qualification

PRODUCT SPECIFICATION

- Relation of approved materials by linking to the test reports and quality certificates

OEE/DTM

- Production yield and downtime management.

- Integrated management of production timing, production workers, preventive or corrective maintenance actions, tests, etc.

MAINTENANCE MANAGEMENT

- Stock and control of spare parts

- Interventions and work orders record (execution times, maintenance intervention, spare parts consumption, worker identification, actions taken, etc)

- Preventive actions plan